close

Choose Your Site

Global

Social Media

loading

| Availability: | |

|---|---|

| Quantity: | |

The four claw grate is a core component designed specifically for coal-fired boilers, biomass combustion equipment, or industrial incinerators. It adopts a unique four claw structure design, aiming to improve fuel combustion efficiency, enhance ventilation performance, and extend equipment service life. Its modular design and high-strength materials make it perform excellently under high temperature and high load conditions, and it is widely used in industrial boilers, thermal power plants, waste incineration and other fields.

Core Features | Four claw structure design, efficient combustion performance, high temperature and wear resistance, modular installation and maintenance |

Technical Parameter | Applicable equipment: Chain grate boiler, reciprocating grate boiler; Working temperature: High temperature customized type; Size specifications: Support customization |

Application scenarios | Industrial boilers (coal-fired/biomass steam boilers, hot water boilers), environmental protection fields (waste incineration power plants), agricultural processing |

Product advantages | Energy saving and consumption reducing, environmental compliance standards, economic durability |

after-sale service | Provide customized design solutions, installation guidance, and lifelong technical support to ensure continuous and efficient operation. |

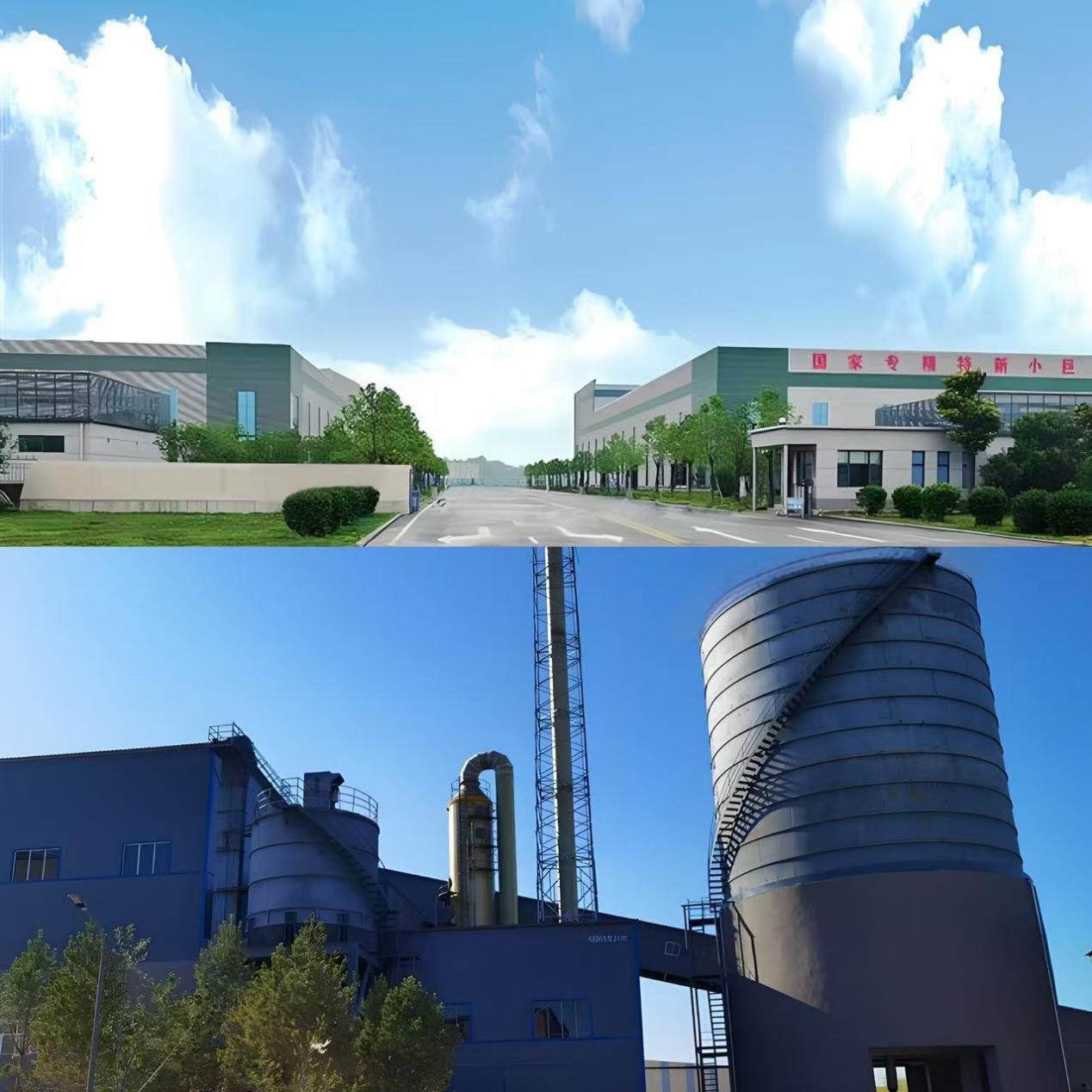

Company Profile

Shandong Jiaguang International is a high-tech enterprise with 30 years of experience in boiler component manufacturing. It has always adhered to the integrated development of R&D, production, sales and technical services. The company has a modern intelligent production base and a professional engineering team of more than 100 people, forming four core product portfolios: high temperature resistant grate system (including active, passive, scale type, reciprocating type), intelligent chain transmission components (including chain rods, scraper conveyor components and sinking scraper chains), precision gas cap devices (boiler gas caps and grates), special pipe solutions (boiler tubes, square tubes and pressure gears), forming a complete boiler component ecosystem.

The company is well-known throughout the country for its excellent product quality and maintains strategic partnerships with the top 15 industrial boiler manufacturers in China, including Harbin Boiler Plant, Dongfang Electric Group, Shanghai Boiler Plant, Jinan Boiler Group, Hangzhou Boiler Group, etc. The company has passed ISO9001 international quality management system certification, CE, SGS certification, and has formed a global service network covering eight major industries such as power generation, thermal energy, papermaking, and chemical industry. The products have been successfully exported to more than 30 countries and regions in Southeast Asia, Central Asia, Oceania, Africa, etc.

As a pioneer in technological innovation in the industry, Shandong Jiaguang International continues to provide full life cycle solutions for global industrial boilers, power plant boilers, and civil heating systems. By continuously improving its R&D capabilities and service system, the company is steadily moving towards becoming a global boiler parts technology benchmark and professional solution provider, and is committed to creating outstanding value for global customers by improving service experience.

Product Packaging

1. Basic packaging method

Single piece packaging: Each four claw grate is usually wrapped in rust proof oil paper or plastic film to avoid surface oxidation or scratching during transportation, especially for rust prone materials such as cast iron and stainless steel.

Batch packaging: after multiple grates are stacked according to specifications, they are loaded into reinforced wooden boxes or iron frame trays, and the interior is filled with foam, bubble film or sawdust cushioning materials to prevent collision damage. Some companies offer customized wooden box sizes to accommodate different specifications of grates (such as lengths ranging from 185-460mm).

2. Protective measures

Place desiccants inside the packaging box to prevent rusting of metal parts in humid environments, especially suitable for sea transportation or long-term storage scenarios.

3. Special packaging services

Export packaging: Some manufacturers provide fumigation wooden boxes or fumigation free plywood boxes that meet international transportation standards, are suitable for container size, and are labeled in English.

Container Type | Length (ft) | Width (ft) | Height (ft) | Volume (cu ft) | Volume (cbm) | Max Payload (kg) | Tare Weight (kg) |

20’Dry Standard | 20 | 8 | 8.6 | 1172 | 33.2 | 28230 | 2300 |

40’Dry Standard | 40 | 8 | 8.6 | 2390 | 67.7 | 26780 | 3900 |

40’High Cube(HC) | 40 | 8 | 9.6 | 2694 | 76.3 | 26500 | 4200 |

45’High Cube(HC) | 45 | 8 | 9.6 | 3040 | 86.1 | 25600 | 4800 |

The four claw grate, with its innovative structure and high reliability, has become an ideal choice for upgrading combustion equipment, helping enterprises achieve efficient and clean energy utilization. For detailed technical solutions or selection suggestions, please contact our engineering team!

FAQ

Q1. Why choose us?

A:We are a modern enterprise specialized in manufacturing and selling.The company has been established for thirty years.We have a lot of experience and good reputation.Every client will be served with our heart.

Q2. how can we guarantee quality?

A:Always a pre-production sample before mass

production;Always final Inspection before shipment.

Q3: How to order?

A:Inquiry-RFQ-Quotation-Sales Order-Payment-Manufacture-Quality Inspection-Package-Delivery

Q4: How about the packaging?

A: Standard export wooden case,iron frame and other seaworthy packing.

Q5: What is your terms of payment?

A: 30%T/T Deposit and 70 % T/T before shipment after inspect well

Q6: What is your advantages?

A:1. Manufacturer, with most competitive price and good quality. 2. technical engineers group offer the best support to you.